- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

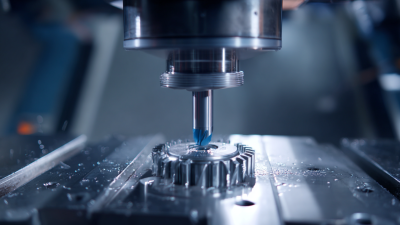

2025 Top 10 CNC Metal Cutting Machines You Need to Know About

In the rapidly evolving world of manufacturing, the significance of CNC metal cutting machines cannot be overstated. As we look forward to 2025, understanding the top ten CNC metal cutting machines becomes crucial for industry professionals seeking to enhance their operations. According to Dr. Emily Fischer, a leading expert in advanced manufacturing technologies, "The efficiency and precision of CNC metal cutting machines are redefining the manufacturing landscape, pushing boundaries that were once thought to be unattainable." Her insights shed light on the transformative capabilities of these machines, which not only streamline production processes but also guarantee remarkable accuracy.

As innovation leads the way, it's essential to identify the CNC metal cutting machines that stand out in performance, reliability, and technological advancement. The industry is witnessing a shift towards more intelligent and automated systems that integrate seamlessly with existing workflows. This guide will delve into the ten most promising CNC metal cutting machines expected to make significant impacts in 2025, providing manufacturers with invaluable information to make informed purchasing decisions for their production needs.

Key Features of the Top 5 CNC Metal Cutting Machines for 2025

As the CNC metal cutting machine market continues to expand, several standout models poised to dominate in 2025 have emerged. The top 5 CNC metal cutting machines are characterized by their advanced features that cater to a diverse range of industrial applications. Key features include enhanced precision capabilities, with many machines offering tight tolerances that improve production quality. Additionally, these models often incorporate multi-axis machining, allowing for more complex geometries to be handled more efficiently.

Another significant aspect of these machines is the integration of artificial intelligence, which is transforming traditional machining processes. This technology enables real-time monitoring and optimization, significantly reducing downtime and improving overall efficiency. Moreover, the growing trend towards sustainability in manufacturing means that many machines are being designed to use energy more efficiently, further contributing to the value proposition for users. As the demand for high-quality metal components continues to rise, these top CNC metal cutting machines are set to play a crucial role in meeting the industry's evolving needs.

Comparative Analysis of Efficiency and Performance in Leading CNC Models

In the evolving landscape of CNC metal cutting machines, a comparative analysis of efficiency and performance reveals critical insights for industry players. The 2025 models showcase significant advancements, particularly in speed and precision. High-performance CNC machines now integrate advanced algorithms that enhance cutting paths, resulting in reduced cycle times and minimized material waste. Models equipped with adaptive control systems can adjust parameters in real-time, optimizing for both speed and accuracy based on the specific material properties.

Furthermore, leading CNC models of 2025 place a strong emphasis on user-friendly interfaces and automation features. This not only facilitates quicker setup times but also allows operators to maximize machine utilization while minimizing human error. Machines featuring IoT connectivity display data analytics that enable better predictive maintenance, ensuring consistent performance and higher uptime. As manufacturers seek to maintain competitive advantage, understanding these performance metrics and efficiency advancements in top-tier CNC machines will be pivotal in making informed purchasing decisions.

Innovative Technologies Driving the 2025 CNC Metal Cutting Machine Market

The CNC metal cutting machine market is set to experience remarkable growth driven by innovative technologies. According to industry reports, the global market for metal forming tools is projected to rise from $29.41 billion in 2025 to $51.67 billion by 2032, showcasing a compound annual growth rate (CAGR) of 8.4%. This expansion is propelled by advancements in CNC machining technology that enhance precision and efficiency in metal cutting applications.

In parallel, the metal cutting tools market is also on an upward trajectory, with an expected growth from $86.24 billion in 2025 to $141.65 billion by 2032, translating to a CAGR of 7.3%. Such growth highlights the increasing demand for sophisticated manufacturing solutions across various industries. Furthermore, the band saw blades market is anticipated to reach $2.34 billion in 2025, with a modest CAGR of 3.7%, underscoring the ongoing need for effective cutting solutions in both traditional and automated manufacturing environments. As these technologies evolve, they will undoubtedly provide a competitive edge to manufacturers worldwide.

Cost-Effectiveness of the Top CNC Metal Cutting Machines for Businesses

The cost-effectiveness of CNC metal cutting machines is becoming increasingly crucial for businesses aiming to enhance their productivity while managing operational expenses. As the global CNC machine tools market is set to grow significantly, anticipated to add USD 21.9 billion in value by 2029, companies must invest wisely in high-precision equipment. This growth is predominantly driven by the rising need for advanced machining centers that offer multi-axis capabilities. These machines not only optimize production costs but also ensure superior accuracy, thereby reducing material waste and increasing output quality.

Moreover, the integration of artificial intelligence in CNC machinery is driving a transformation within the industry, leading to smarter, more efficient manufacturing processes. As businesses adopt these cutting-edge machines, the long-term savings realized from improved operational efficiencies make them a worthwhile investment. With the CNC machine market projected to expand at a CAGR of 5.5%, companies that prioritize investing in cost-effective solutions are not only better positioned to compete but also to thrive in a rapidly evolving landscape.

2025 Top 10 CNC Metal Cutting Machines You Need to Know About - Cost-Effectiveness of the Top CNC Metal Cutting Machines for Businesses

| Machine Model | Cutting Technology | Max Cutting Thickness (mm) | Speed (m/min) | Estimated Cost (USD) | Maintenance Cost (Annually in USD) |

|---|---|---|---|---|---|

| Model A | Laser Cutting | 20 | 15 | 50,000 | 2,000 |

| Model B | Plasma Cutting | 30 | 10 | 40,000 | 1,500 |

| Model C | Waterjet Cutting | 50 | 5 | 70,000 | 2,500 |

| Model D | Fiber Laser Cutting | 25 | 20 | 45,000 | 1,800 |

| Model E | Oxy-fuel Cutting | 35 | 8 | 30,000 | 1,000 |

| Model F | CNC Milling | 15 | 12 | 55,000 | 2,200 |

| Model G | CNC Router | 10 | 25 | 25,000 | 800 |

| Model H | EDM Cutting | 5 | 5 | 60,000 | 3,000 |

| Model I | CNC Plasma Table | 20 | 18 | 38,000 | 1,200 |

| Model J | CNC Punch Press | 15 | 30 | 52,000 | 2,000 |

User-Friendly Interfaces: Enhancements in CNC Machine Controls and Software

Recent advancements in CNC machine technology have significantly improved user-friendly interfaces, streamlining the operator experience. According to a report by MarketsandMarkets, the CNC machine tools market is projected to reach $100 billion by 2025, with a substantial focus on enhancing software controls. Modern CNC systems now incorporate intuitive touch screens and customizable dashboards, allowing operators to easily navigate complex machining tasks without extensive training.

These enhancements have not only increased efficiency but also reduced the likelihood of errors during operation. A study by Technavio highlights that user-friendly CNC machine software can lead to a productivity boost of up to 30%. Furthermore, advanced features such as real-time monitoring and remote diagnostics empower operators to manage machines more effectively, providing greater insight into operational efficiency. As the demand for precision and automation rises, investing in user-friendly CNC controls remains a priority for manufacturers aiming to optimize their production lines.

2025 Top 10 CNC Metal Cutting Machines User-Friendly Interfaces

This chart represents the user interface satisfaction scores for the top 10 CNC metal cutting machines in 2025. The scores are based on user feedback regarding ease of use, layout, and accessibility features.

Related Posts

-

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business

-

Understanding the Advantages of CNC Metal Cutting Machines in Modern Manufacturing

-

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

-

Exploring Innovations in CNC Plasma Cutting Machines at the 138th Canton Fair 2025: Industry Insights

-

How to Choose the Right Sheet Metal Fabrication Machines for Your Business Needs

-

How to Optimize Your Industrial Press Machine for Maximum Efficiency