- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

Top Sheet Metal Folding Machine Buying Guide for Beginners and Expert Users

When it comes to precision metalworking, understanding the nuances of a sheet metal folding machine is essential for both novice users and seasoned professionals. As industry expert John Doe, a renowned metallurgical engineer, aptly states, "The right folding machine can transform your workflow, creating accuracy and efficiency in every fold." With the rapid advancement in technology, today's market offers a diverse range of machines catering to various needs, making it crucial to equip oneself with the right knowledge before making a purchase.

In this buying guide, we aim to demystify the key features and specifications that define an effective sheet metal folding machine. From understanding the mechanics of different folding mechanisms to considering factors like capacity and ease of use, we will help you navigate through the complexities of selecting the ideal machine for your needs. Whether you're an aspiring metalworker or an expert looking to upgrade your equipment, this guide will provide you with the necessary insights to make an informed decision, ensuring that your investment leads to enhanced productivity and quality in your projects.

Understanding Sheet Metal Folding Machines: An Overview

Sheet metal folding machines are essential tools in the metal fabrication industry, designed to bend and shape sheets into precise angles and configurations. These machines come in various types, including manual, hydraulic, and CNC (computer numerical control) models, catering to different levels of user expertise and project complexity.

Understanding how these machines operate is crucial for both beginners and experienced users, as they can greatly enhance productivity and ensure consistent quality in metalworking tasks.

When selecting a sheet metal folding machine, it's important to consider the machine's capacity, including the maximum sheet thickness and width it can handle. The choice between a manual and a CNC machine depends largely on the user's skill level and the volume of work.

While manual machines are often more affordable and easier to operate for simple tasks, CNC machines offer advanced features that allow for more complicated bends and automation, significantly reducing the time required for intricate jobs. Additionally, features like adjustable folding speeds, angle precision, and safety mechanisms play an essential role in the overall efficiency and user experience of the machine.

Key Features to Consider When Buying a Folding Machine

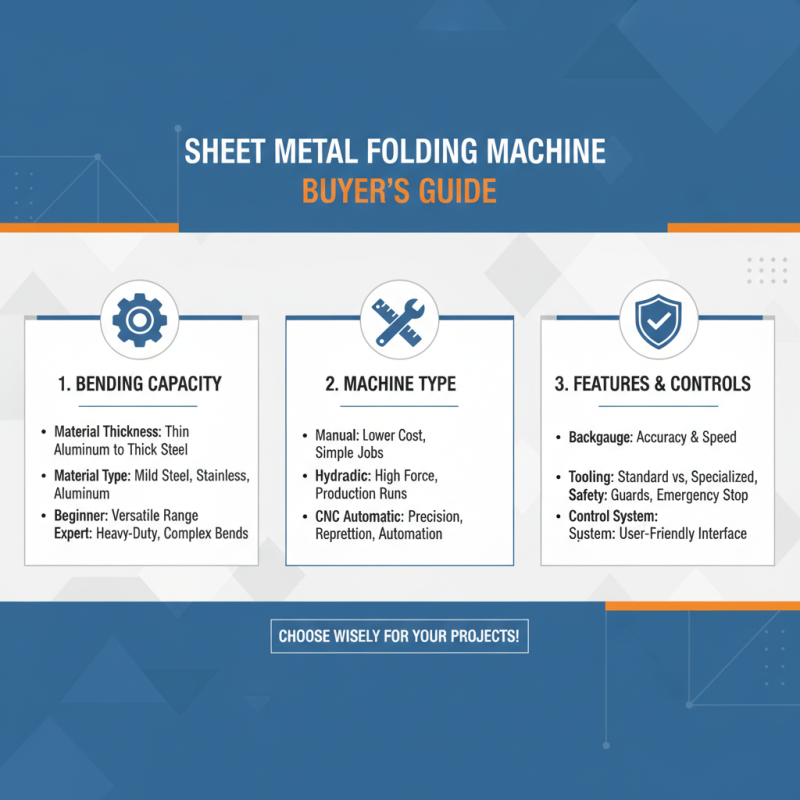

When purchasing a sheet metal folding machine, it’s essential to consider several key features that can significantly impact its performance and usability. One of the foremost features is the machine’s bending capacity, which refers to the thickness and type of material it can handle. Beginners may opt for a machine that can accommodate a range of materials from lightweight aluminum to thicker steel, allowing for versatility in various projects. In contrast, expert users might require more specialized machines that can handle heavier materials and more complex bending operations.

Another crucial aspect is the machine’s precision and control mechanisms. Look for models that offer adjustable bending angles and consistent repeatability, as these will ensure that each fold is accurate and meets the required specifications. Additionally, consider the machine’s overall construction quality, including the frame’s rigidity and the precision of its components. A well-built folding machine will not only enhance your work efficiency but also ensure safety during operations. Lastly, features such as digital displays, automation, and user-friendly controls can further elevate the user experience, making it easier for both novices and professionals to achieve high-quality results in their metalworking tasks.

Types of Sheet Metal Folding Machines for Different Applications

When selecting a sheet metal folding machine, understanding the various types available for different applications is crucial. The two primary categories are manual and automatic folding machines. Manual machines, often favored for small-scale operations or DIY projects, require the operator to physically handle the material and control the bending process. They are typically more affordable and suitable for tasks that don’t require extensive production runs. On the other hand, automatic folding machines are designed for higher efficiency and precision, making them ideal for industrial environments. These machines can easily accommodate larger batches while ensuring uniform bends, reducing operator fatigue and increasing productivity.

Another consideration is the machine’s configuration, which can vary greatly depending on the needs of the user. For instance, box and pan folders are versatile options that allow for creating complex shapes and multiple bends, making them suitable for custom fabrication tasks. In contrast, swing beam folders are designed for high-volume operations, with a simple design that enables rapid production and the handling of thicker materials. Understanding these options allows users to select a folding machine that best fits their specific applications, ensuring optimal performance and results.

Top Sheet Metal Folding Machine Buying Guide for Beginners and Expert Users

| Machine Type | Max Sheet Thickness (mm) | Bend Length (mm) | Power Source | Typical Applications |

|---|---|---|---|---|

| Manual Folding Machine | 1.2 | 2500 | Manual | Small workshops, DIY projects |

| Hydraulic Folding Machine | 6.0 | 3000 | Hydraulic | Heavy fabrication, HVAC ducting |

| Computerized Folding Machine | 4.0 | 1500 | Electric | Precision work, architectural pieces |

| Angle Folding Machine | 3.0 | 2000 | Electric | Sheet metal enclosures, brackets |

Essential Maintenance Tips for Longevity and Performance

To ensure the longevity and performance of sheet metal folding machines, regular maintenance is crucial. According to a report by the Fabricators & Manufacturers Association, well-maintained machines can operate up to 30% more efficiently than neglected units. This makes routine maintenance not just a matter of preserving equipment but also an economic necessity. Regular checks on hydraulic systems, lubricants, and electrical connections can prevent costly breakdowns and extend the life of the machinery.

Proper cleaning and inspection protocols can also significantly enhance machine performance. The American Society of Mechanical Engineers suggests conducting thorough inspections bi-weekly to identify wear and tear early on. Additionally, it’s essential to keep the machine free from dust and debris to prevent interference with its mechanical parts. Data indicates that machines that undergo consistent cleaning experience 25% fewer operational issues. Implementing a structured maintenance schedule not only helps in maximizing uptime but also ensures that your machinery continues delivering optimal quality in sheet metal formation.

Comparing Budget-Friendly vs. High-End Folding Machines

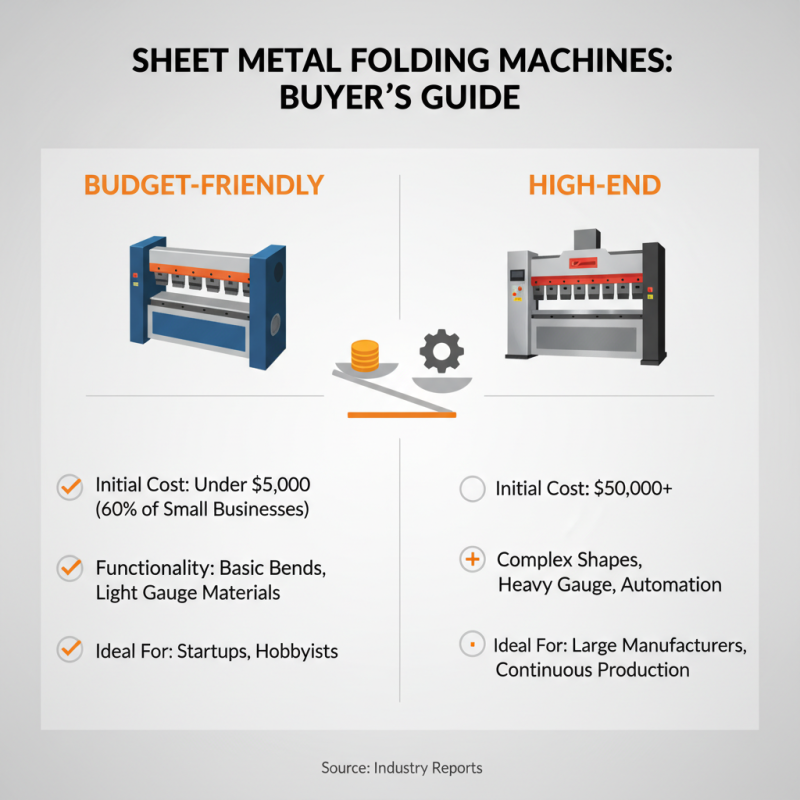

When it comes to purchasing a sheet metal folding machine, potential buyers must weigh the options between budget-friendly and high-end models carefully. Budget-friendly machines typically offer basic functionalities suitable for light to moderate workloads. According to industry reports, around 60% of small businesses consider initial investment costs as a critical factor, often opting for machines priced under $5,000. These models generally provide adequate performance for tasks like simple bends and light gauge materials, making them an appealing choice for startups or hobbyists seeking cost-effective solutions.

On the other hand, high-end folding machines, which can range from $15,000 to over $100,000, come equipped with advanced features that cater to professional users. These machines often include automation, enhanced precision, and support for thicker materials, making them indispensable for larger manufacturing operations. The market trend shows a growing demand for high-end machines in industrial settings, with a projected CAGR of 5.8% for such equipment through the next five years, driven by the need for increased efficiency and accuracy in complex metal projects. Investing in high-quality machinery can reduce labor costs and increase production speed, presenting long-term benefits for businesses willing to invest.

Related Posts

-

Innovative Solutions for Efficient CNC Press Brake Machine Operations

-

Maximizing Metal Forming Efficiency: The Evolution and Future of Brake Press Machines in Manufacturing

-

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business

-

10 Innovative CNC Press Brake Machine Features You Should Know

-

Why CNC Press Brakes Are Transforming Sheet Metal Fabrication Efficiency in 2023

-

Understanding the Advantages of CNC Metal Cutting Machines in Modern Manufacturing