- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

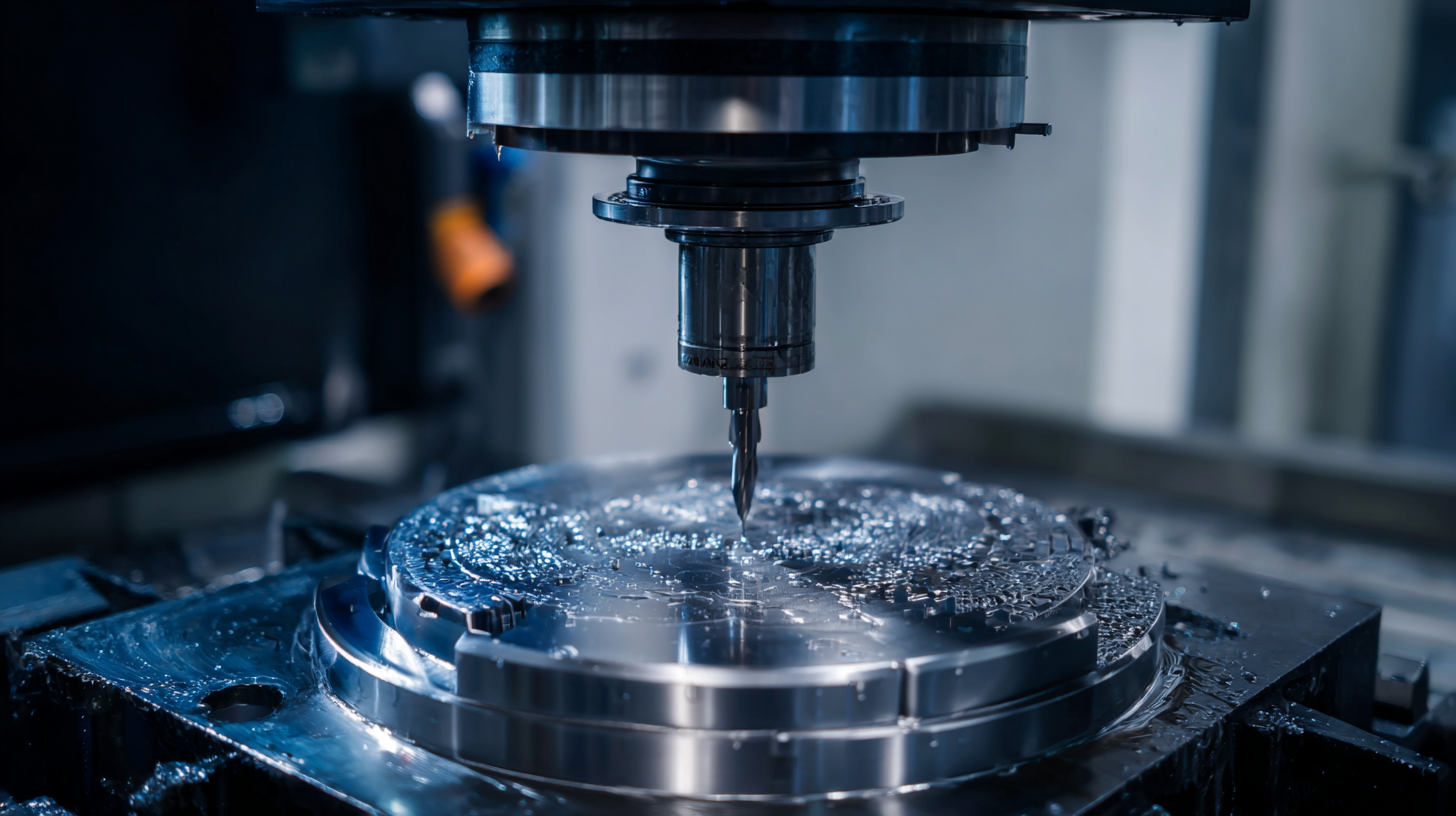

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

As the manufacturing landscape evolves, the integration of advanced technologies such as CNC cutting machines has become pivotal in enhancing precision and efficiency. According to a recent report by Mordor Intelligence, the global CNC machine market is projected to grow at a CAGR of 6.1%, reaching USD 100 billion by 2026, driven by the increasing demand for automation in industrial processes. CNC cutting machines sit at the forefront of this revolution, providing manufacturers with the ability to execute intricate designs with unparalleled accuracy. With their ability to reduce waste and improve operational efficiency, these machines are becoming indispensable in sectors ranging from automotive to aerospace. As manufacturers seek to adopt smarter and more adaptable systems, the future of CNC cutting machines looks promising, promising not just enhanced precision but also cost-effective production methods essential for competing in the modern marketplace.

The Evolution of CNC Cutting Machines in Modern Manufacturing

The evolution of CNC cutting machines is fundamentally reshaping modern manufacturing, reflecting a significant shift towards digital technologies that enhance productivity across various sectors. The global CNC machine market is projected to expand at a compound annual growth rate (CAGR) of 5.5%, highlighting the increasing importance of precision and automation in manufacturing processes. These advancements enable manufacturers to achieve greater accuracy and efficiency, particularly in high-value industries such as aerospace and automotive.

One of the key innovations driving this evolution is the development of automated calibration systems, which minimize the reliance on manual adjustments and optimize measurement accuracy. These systems not only enhance precision but also reduce operational downtime, allowing manufacturers to respond more effectively to market demands. Furthermore, the integration of AI-powered technologies is paving the way for smarter manufacturing solutions, where optimization techniques and data analytics contribute to the production of high-quality and tailored products. As these technologies continue to advance, CNC cutting machines will remain at the forefront of reshaping the manufacturing landscape, enabling industries to meet the challenges of precision engineering head-on.

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

| Machine Type | Precision Level | Material Compatibility | Typical Applications | Future Trends |

|---|---|---|---|---|

| Laser Cutting Machine | Up to 0.01 mm | Metal, Wood, Acrylic | Signage, Automotive Parts | Increased automation, AI integration |

| Plasma Cutting Machine | Up to 0.3 mm | Metal (Steel, Aluminum) | Structural Steel, Fabrication | Improved speed, portability options |

| Waterjet Cutting Machine | Up to 0.05 mm | Metal, Glass, Stone | Aerospace, Stone Cutting | Eco-friendly solutions, innovative nozzles |

| CNC Router | Up to 0.1 mm | Wood, Plastic, Composites | Furniture, Sign Making | Smart manufacturing, modular designs |

Key Technologies Driving Precision in CNC Cutting

The advancement of CNC cutting machines is being driven by a wave of innovative technologies, enhancing precision and efficiency in modern manufacturing. Key technologies such as laser optics, CNC plasma cutting, and advanced woodworking tools are fundamentally transforming various industries. For instance, the woodworking CNC tools market is anticipated to grow from USD 8.2 billion in 2025 to USD 13.4 billion by 2035, reflecting a robust CAGR of 5.0%. This growth signifies a mounting demand for precision in wood processing, driven by the increasing adoption of automated solutions.

Moreover, the CNC plasma cutting machines market is projected to expand significantly, with an anticipated value of USD 1.1 billion by 2034. As industries strive for higher accuracy and reduced wastage, the integration of laser optics in CNC cutting processes plays a pivotal role. This sector is witnessing advancements in laser technology, which facilitate improved cutting quality and operational efficiency.

**Tip:** When investing in CNC cutting machines, consider the scalability of the technology and its compatibility with your existing systems to ensure a seamless integration that boosts your manufacturing capabilities.

**Tip:** Regular training for operators on the latest CNC technologies can lead to more effective and efficient machine use, directly impacting productivity and precision.

Comparative Analysis: Traditional vs. CNC Cutting Methods

The landscape of modern manufacturing is rapidly evolving, with CNC (Computer Numerical Control) cutting machines emerging as a game-changer compared to traditional cutting methods. According to a report by IBISWorld, the CNC machining industry is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2026, driven by increasing demand for precision and automation. Traditional methods, while effective, often fall short in terms of accuracy and efficiency. CNC machines offer tighter tolerances, enabling manufacturers to produce complex geometries with up to 0.001 mm precision, a feat difficult to achieve with manual tools.

Moreover, the time efficiency of CNC cutting is significantly superior. A study by Statista indicates that CNC machining can reduce production time by as much as 75%, allowing companies to meet tighter deadlines and respond swiftly to market demands. In contrast, traditional methods are labor-intensive and often involve longer setup times. As manufacturers increasingly seek to optimize their operations and enhance product quality, the transition to CNC technology becomes not just advantageous but essential for staying competitive in today’s fast-paced industrial landscape.

Future Trends: AI and Automation in CNC Cutting

The integration of AI and automation in CNC cutting machines marks a pivotal shift in modern manufacturing. As industries strive for greater efficiency, these advanced technologies are revolutionizing how precision cutting is approached. AI algorithms are capable of optimizing cutting paths, reducing waste, and ensuring higher accuracy, all while adapting to real-time feedback from the machining process. This means that manufacturers can achieve higher throughput without sacrificing quality, carving out a competitive edge in a rapidly evolving market.

Moreover, automation enhances the scalability of CNC operations. With the capability to quickly switch between different tasks, automated systems can manage multiple production requirements seamlessly. This flexibility allows manufacturers to respond to changing consumer demands without additional strain on labor resources. The future of CNC cutting machines, therefore, lies in harnessing the power of AI and automation, ensuring that manufacturers not only keep pace with technological advancements but also set the benchmark for innovation and efficiency in the manufacturing sector.

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

This chart illustrates the projected growth of the global CNC machine market from 2019 to 2023. As the integration of AI and automation advances, it is anticipated that the market will continue to expand significantly, reflecting the increasing demand for precision in modern manufacturing.

Best Practices for Optimizing CNC Cutting Machine Performance

Optimizing the performance of CNC cutting machines is critical in the quest for precision and efficiency in modern manufacturing. According to a report by Technavio, the global CNC cutting machine market is projected to grow by over $4 billion from 2020 to 2024, highlighting the high demand for enhanced machine performance. One of the best practices to achieve this optimization is through regular maintenance and calibration. Machine downtime due to malfunctions can lead to significant losses, estimated at $50 billion annually across the manufacturing sector, emphasizing the need for routine checks to ensure accuracy and reliability.

Optimizing the performance of CNC cutting machines is critical in the quest for precision and efficiency in modern manufacturing. According to a report by Technavio, the global CNC cutting machine market is projected to grow by over $4 billion from 2020 to 2024, highlighting the high demand for enhanced machine performance. One of the best practices to achieve this optimization is through regular maintenance and calibration. Machine downtime due to malfunctions can lead to significant losses, estimated at $50 billion annually across the manufacturing sector, emphasizing the need for routine checks to ensure accuracy and reliability.

Another effective approach is the integration of advanced software that utilizes AI and machine learning for predictive analysis. Research from McKinsey suggests that manufacturers employing these technologies can improve production efficiency by 20-25%. By analyzing historical data, these systems can anticipate potential issues before they arise, allowing for proactive maintenance and reducing unplanned downtimes. Additionally, optimizing cutting parameters like feed rate and spindle speed can significantly enhance the quality of finished products while reducing material waste, further contributing to cost-effectiveness in operations.

Related Posts

-

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business

-

Understanding the Advantages of CNC Metal Cutting Machines in Modern Manufacturing

-

5 Compelling Reasons to Choose a CNC Cutting Machine for Your Business

-

Exploring Innovative Uses of Sheet Metal Fabrication Machines in Modern Industries

-

Ultimate Guide to Mastering Roll to Sheet Cutting Machines for Optimal Production Efficiency

-

How to Optimize Your CNC Plasma Cutting Machine for Maximum Efficiency and Precision