- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

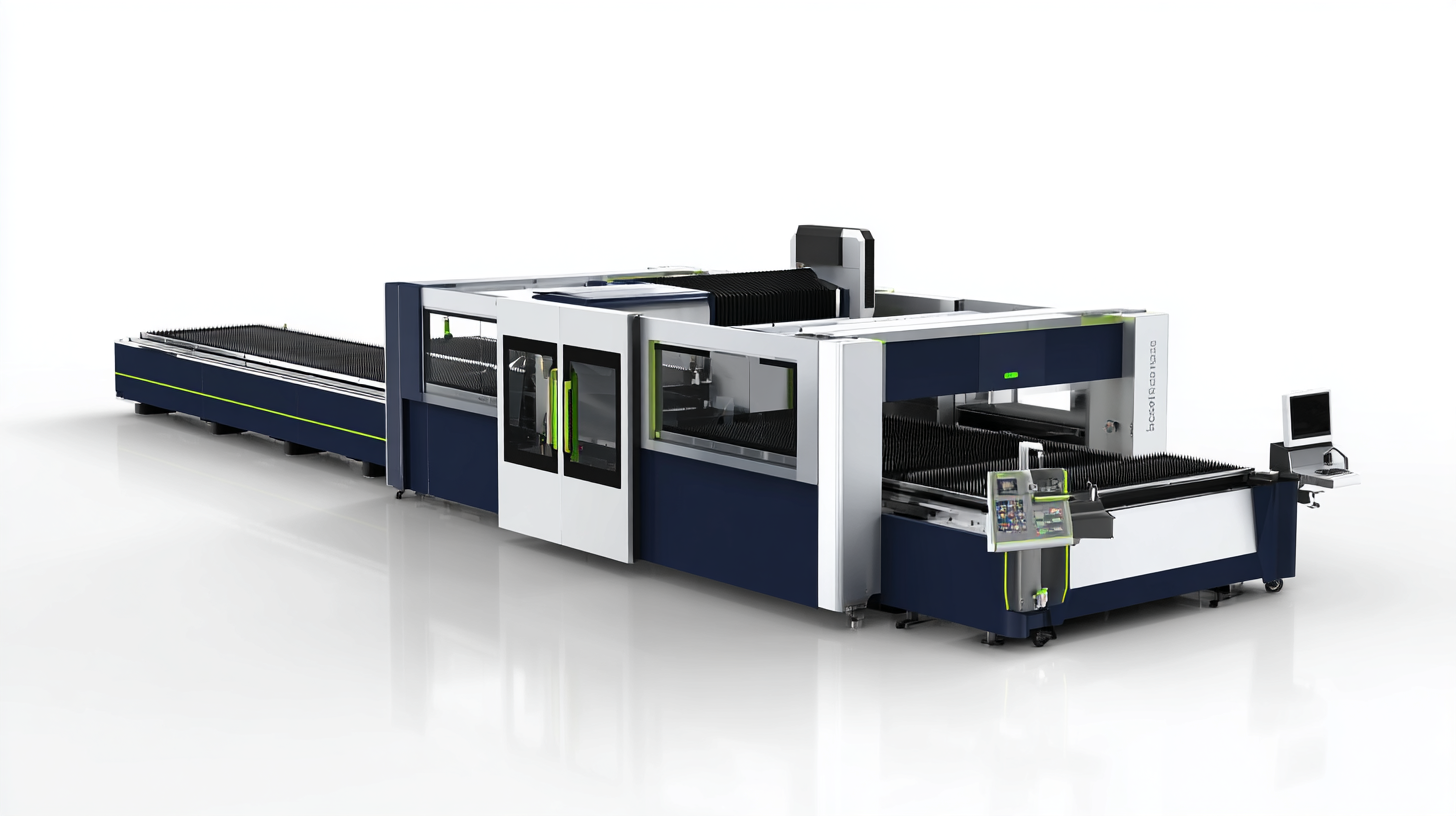

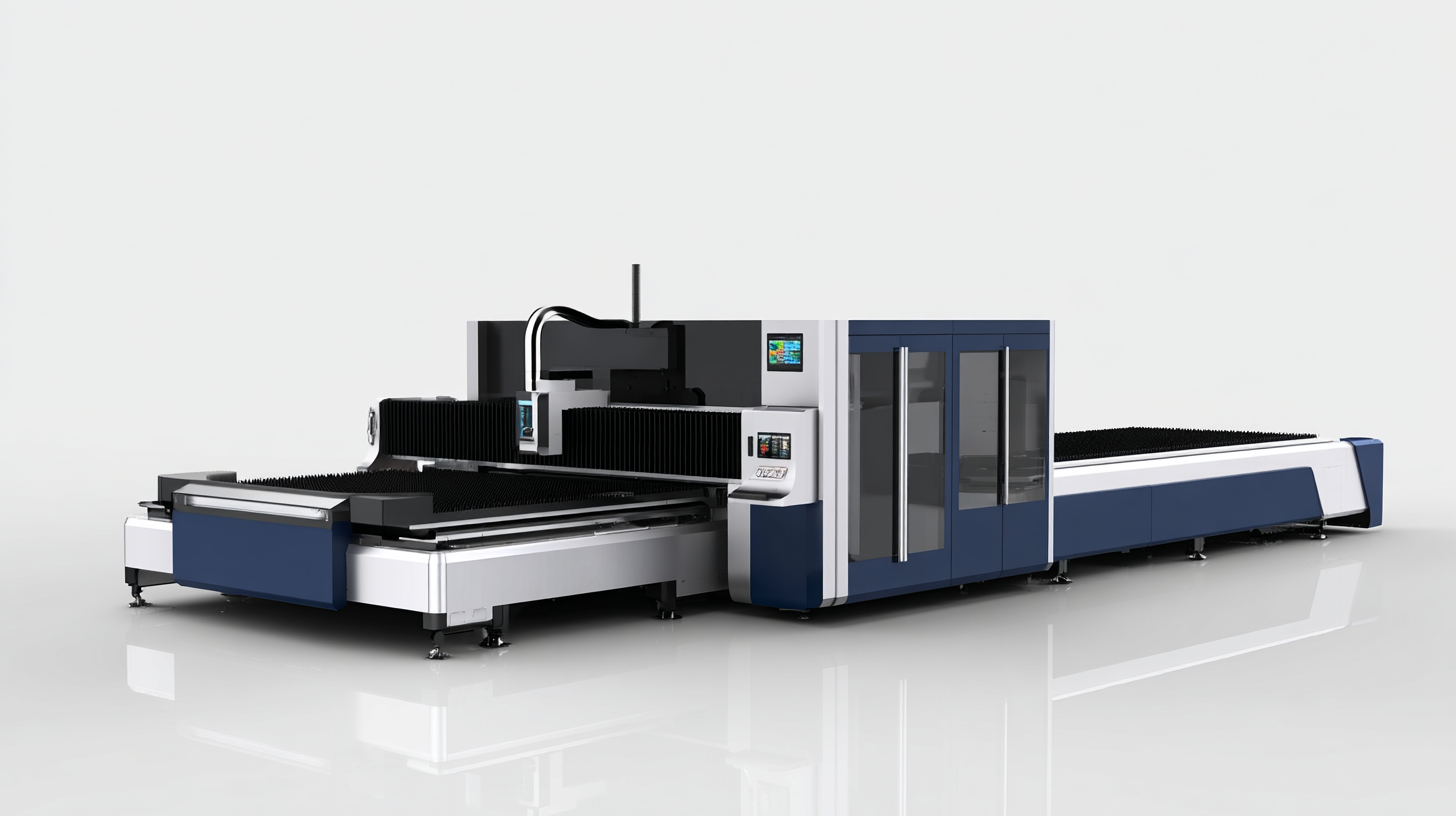

Maximize Your Efficiency with Advanced Sheet Metal Laser Cutting Machines for Precision Production

In the fast-paced world of manufacturing, maximizing efficiency without compromising on precision is paramount. The advent of advanced sheet metal laser cutting machines has revolutionized the production process, allowing manufacturers to achieve unparalleled accuracy and speed in their operations. These machines utilize cutting-edge technology to deliver clean, precise cuts consistently, reducing material waste and increasing overall productivity.

As industries strive to meet the demands of custom fabrication and intricate designs, the importance of integrating high-performance sheet metal laser cutting machines cannot be overstated. This article will explore the numerous advantages these machines bring to the table, how they optimize workflow, and why investing in such technology is essential for companies aiming to stay competitive in today's market.

As industries strive to meet the demands of custom fabrication and intricate designs, the importance of integrating high-performance sheet metal laser cutting machines cannot be overstated. This article will explore the numerous advantages these machines bring to the table, how they optimize workflow, and why investing in such technology is essential for companies aiming to stay competitive in today's market.

Understanding the Basics of Sheet Metal Laser Cutting Technology

Sheet metal laser cutting technology has evolved significantly, becoming a cornerstone of precision production in various industries. This advanced method utilizes fiber lasers that generate highly concentrated beams of light, allowing for clean and accurate cuts in a variety of metal thicknesses. Understanding the basics of this technology is essential for maximizing efficiency in manufacturing processes. The capability to produce complex shapes with high-speed precision not only enhances productivity but also reduces material waste, making it a cost-effective solution for fabricators.

Operators equipped with a strong grasp of the foundational elements of laser cutting quality can significantly impact the overall performance of the machinery. Factors such as beam quality, focus, and cutting speed must be carefully calibrated to ensure optimal results. Even with automation, the skill and knowledge of the operator remain critical to prevent issues like part tipping, which can disrupt the cutting process. As the global fiber laser cutter market continues to grow—expected to reach USD 3.35 billion by 2034—investing in training and understanding the basics of this technology becomes increasingly vital for future success in the field.

Identifying Key Features to Look for in Laser Cutting Machines

When selecting advanced sheet metal laser cutting machines for precision production, it’s crucial to identify key features that enhance operational efficiency. One of the primary aspects to consider is the machine’s laser source. CO2 lasers, for instance, offer excellent precision and are suitable for cutting various materials, while fiber lasers are more efficient for metal cutting, providing higher speed and lower operational costs.

Another vital feature is the cutting area and bed size. A larger cutting surface allows for versatile production runs and reduces the need for repositioning materials, thereby increasing throughput. It’s also important to evaluate the software used for controlling the machine. Advanced software can offer intuitive designs, nesting capabilities, and integration with other systems, which significantly streamlines the production process.

**Tips:** Always assess the machine's maintenance requirements and support options offered by the manufacturer. Regular maintenance is essential for optimal performance and longevity. Additionally, consider investing in a machine with modular upgrades to stay current with technological advancements and changing production needs, ensuring your investment remains relevant and efficient.

Efficiency Comparison of Advanced Sheet Metal Laser Cutting Machines

Tips for Optimizing Laser Cutting Settings for Enhanced Efficiency

When it comes to precision production in sheet metal fabrication, advanced laser cutting machines have revolutionized the industry. To harness their full potential, understanding how to optimize laser cutting settings is crucial for maximizing efficiency.

One effective tip is to adjust the cutting speed based on material thickness. Thinner materials can handle faster speeds, which can increase throughput without sacrificing quality. Conversely, for thicker sheets, slowing down the cutting speed enhances the beam's ability to penetrate, resulting in cleaner cuts. Additionally, the focal point of the laser should be finely tuned to ensure optimal cutting performance. A properly adjusted focus can lead to improved cut quality and reduced edge burrs, minimizing the need for secondary finishing processes.

Another important factor is the gas assist used during cutting. Selecting the right gas and pressure can significantly impact the quality of the cut and the cutting speed. For stainless steel, oxygen can enhance cutting speed but may result in oxidization at the edge. Conversely, nitrogen might yield cleaner edges without oxidation, ideal for situations where post-processing is limited. Balancing these variables not only enhances the overall efficiency of the process but also contributes to significant cost savings in production.

Integrating Automation and Software Solutions in Laser Cutting Workflows

The integration of automation and software solutions in laser cutting workflows is transforming the landscape of sheet metal production. Advanced laser cutting machines, equipped with smart technology, allow for seamless communication between different stages of the manufacturing process. By automating repetitive tasks, these systems not only enhance operational efficiency but also reduce the potential for human error, leading to more consistent and precise cuts.

Furthermore, sophisticated software solutions play a crucial role in optimizing laser cutting operations. They enable operators to efficiently program their machines, monitor real-time performance, and make data-driven adjustments on the fly. This not only streamlines workflow management but also supports advanced planning methods, such as just-in-time production, which can significantly lower material waste. As manufacturers adopt these integrated solutions, they can better meet the demands for high-quality products while also maximizing their productivity and profitability.

Maintenance Best Practices for Prolonging the Lifespan of Laser Cutters

Maintaining advanced sheet metal laser cutting machines is crucial for achieving optimal efficiency and precision in production. Regular maintenance not only prolongs the lifespan of such machines but also ensures that they operate at peak performance. According to industry reports, scheduled preventative maintenance can reduce unplanned downtime by up to 30%, leading to significant cost savings over time. This is particularly important in sectors that rely heavily on precision cutting, where even slight deviations can result in material waste and increased operational costs.

One of the best practices for maintaining laser cutters includes regularly checking and cleaning optical components. Dust and debris can severely affect cutting quality and machine performance. Furthermore, keeping the cutting head and nozzle in top condition can enhance the precision of the cuts and reduce the need for rework. Additionally, monitoring the alignment of the laser beam is essential, as a misaligned beam can lead to inconsistent cutting results and equipment wear. By adhering to these maintenance best practices, manufacturers can ensure their laser cutting technology continues to deliver high-quality production outcomes efficiently.

Maximize Your Efficiency with Advanced Sheet Metal Laser Cutting Machines for Precision Production - Maintenance Best Practices for Prolonging the Lifespan of Laser Cutters

| Maintenance Practice | Frequency | Benefits | Potential Issues if Ignored |

|---|---|---|---|

| Regular Cleaning of Lenses | Daily | Maintains optimal beam quality | Decreased cutting efficiency and quality |

| Check Water Chiller Levels | Weekly | Prevents overheating | Risk of laser tube damage |

| Inspect and Replace Protective Windows | Monthly | Ensures safety and visibility | Increased risk of accidents |

| Lubricate Moving Parts | Monthly | Reduces wear and tear | Mechanical failures |

| Software Updates | Quarterly | Implements new features and fixes | Loss of efficiency and bugs |

| Annual Comprehensive Inspections | Yearly | Identifies potential failings | Major breakdowns |

Related Posts

-

7 Best Practices for Using a Metal Sheet Bending Machine Effectively

-

How to Choose the Right Metal Shear Machine for Your Business Needs

-

Innovative Solutions for Efficient CNC Press Brake Machine Operations

-

How to Optimize Your Industrial Press Machine for Maximum Efficiency

-

8 Compelling Reasons to Invest in a Bending Machine for Your Business

-

Exploring Innovative Uses of Sheet Metal Fabrication Machines in Modern Industries