- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

10 Essential Tips for Choosing the Right Sheet Cutting Machine for Your Needs

In today’s manufacturing landscape, the importance of selecting the right sheet cutting machine cannot be overstated. According to John Smith, a renowned expert in the sheet cutting industry, “The efficiency and precision of your production line will largely depend on the cutting machine you choose.” This statement highlights the crucial role that these machines play in ensuring product quality and operational effectiveness.

When considering a sheet cutting machine, manufacturers must evaluate their specific needs, including material types, production volume, and desired cut accuracy. A well-chosen machine can not only enhance productivity but also reduce waste and operational costs. Therefore, understanding the key factors involved in this decision-making process is vital for any business looking to improve its manufacturing capabilities.

As we delve into the essential tips for choosing the right sheet cutting machine, it becomes clear that making an informed choice requires careful consideration of various elements. From technological features to after-sale support, each aspect plays a significant role in the ultimate performance of the machine.

Understanding Different Types of Sheet Cutting Machines Available Today

When selecting a sheet cutting machine, it's crucial to understand the various types available in today's market. The most common options include rotary cutting machines, guillotine cutters, and die cutters. Rotary cutting machines are often favored for their precision and ability to handle different materials, making them suitable for both small and large-scale operations. According to industry reports, the demand for rotary cutters has seen a growth of approximately 15% annually, largely due to their versatility.

Guillotine cutters, on the other hand, are ideal for thicker sheets and are popular in industries such as printing and packaging. Their straightforward mechanism allows for quick and efficient cutting, which is essential in high-volume production settings. A recent survey indicated that 40% of manufacturers value speed and efficiency as their top priorities when investing in cutting technology.

Tip: Before making a purchase, assess the materials you'll be working with and the desired cutting capacity. This will help you choose a machine that best fits your specific requirements.

Die cutters are another option, particularly useful for creating intricate shapes and designs. Their precision makes them a preferred choice among graphic designers and artisans. A report published by the Manufacturing Association highlighted that nearly 30% of professionals in the design field are now utilizing die cutting machines for their creative projects.

Tip: Always consider the maintenance and operational costs associated with each type of machine. Investing in a more durable model might incur higher upfront costs but can save you significant expenses in the long run.

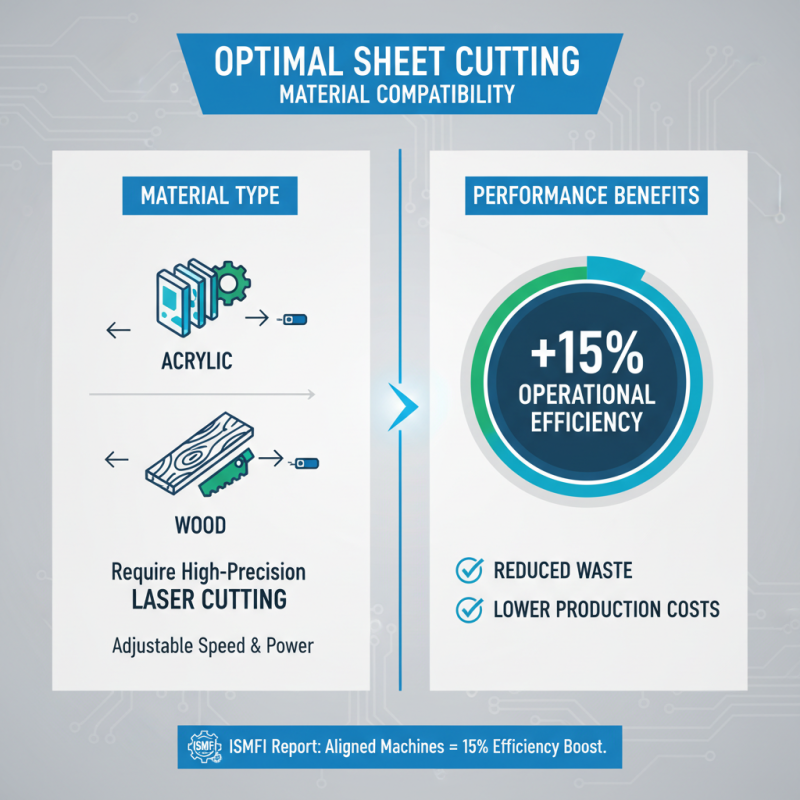

Evaluating Material Compatibility: What to Consider for Optimal Cutting

When selecting a sheet cutting machine, evaluating material compatibility is crucial for achieving optimal performance and efficiency. Different materials require specific cutting techniques and machine capabilities. For example, materials like acrylic and wood require machines equipped with high-precision laser cutting technology, which operates at various speeds and powers to accommodate the varying densities and melt points of these materials. According to a report by the International Sheet Metal and Fabrication Industry (ISMFI), companies that align their cutting machines with their material types see a 15% increase in operational efficiency, reducing waste and production costs.

Furthermore, understanding the thickness and type of materials will directly impact the choice of cutting machine. Each material, whether it be composite, plastic, or metals, has unique properties such as tensile strength and thermal conductivity that influence the cutting process. A study published in the Journal of Manufacturing Processes highlighted that choosing the correct cutting machine based on material compatibility can extend the lifespan of the equipment by up to 20%. This not only minimizes the frequency of repairs but also ensures consistent quality in production runs, which is vital in meeting tight market demands.

Key Features to Look for in Sheet Cutting Machines and Their Benefits

When selecting the right sheet cutting machine, there are several key features to consider that can significantly impact performance and efficiency. First and foremost, the cutting capacity is crucial; it determines the maximum thickness and size of the sheets the machine can handle. A model that accommodates a range of materials, such as paper, plastic, and metal, provides versatility for various applications. Additionally, precision is essential; machines equipped with advanced cutting technology ensure clean, accurate cuts that reduce material waste and enhance the quality of the final product.

Another important feature is the speed of operation. A machine that offers adjustable cutting speeds can cater to both small-scale projects and high-volume production runs. This flexibility helps optimize workflow and productivity. Safety features are also vital; look for machines with automatic shut-off functions, safety guards, and user-friendly controls. These elements ensure a secure working environment and minimize the risk of accidents.

Lastly, ease of maintenance should not be overlooked; machines designed for simple upkeep help prolong the equipment's lifespan and ensure consistent performance over time.

Analyzing Production Capacity and Efficiency Metrics in Sheet Cutting

When selecting the right sheet cutting machine, understanding production capacity and efficiency metrics is crucial. These elements directly impact your ability to meet demand and optimize manufacturing processes. Analyzing the machine's throughput—the number of sheets it can cut in a specific time frame—helps you gauge whether it fits your production needs. Look beyond just speed; consider the machine's rest time between cuts and how quickly it can be set up or adjusted for different projects.

To ensure you make the right choice, start by assessing your production volume requirements. If your operations demand high output levels, invest in a machine with greater capacity and automation features. Also, examine the material compatibility, as cutting performance can vary widely depending on the type of sheet you are working with. Additionally, evaluating energy consumption can reveal efficiency metrics that affect your overall operational costs.

Remember, efficiency is not just about speed. Seek machines that not only cut quickly but also minimize waste through precise measurements. Reviewing user feedback and conducting thorough research can help clarify these metrics, guiding you to a well-informed decision. By focusing on capacity and efficiency, you can find a sheet cutting machine that aligns with your production goals while enhancing operational performance.

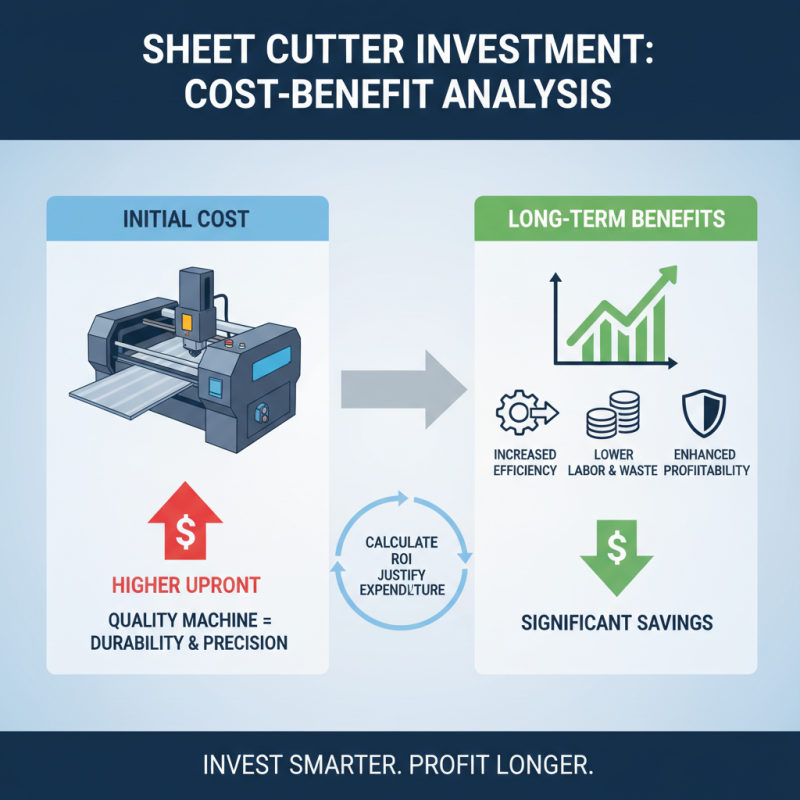

Cost-Benefit Analysis: Investing in Quality Sheet Cutting Machines

When investing in a sheet cutting machine, it's crucial to conduct a thorough cost-benefit analysis to ensure that you make a sound financial decision. High-quality machines may come with a higher upfront cost, but they often provide better durability, accuracy, and efficiency, which can translate into significant savings over time. For businesses, the production efficiency of a quality machine can lead to lower labor costs and reduced material waste, enhancing overall profitability. By calculating the long-term benefits against the initial investment, you can determine whether the extra expenditure is justified.

Additionally, consider the operational costs associated with maintenance and repairs. High-quality machines typically have a longer lifespan and require fewer replacements, minimizing disruption to your production schedule. Investing in a reliable sheet cutting machine means less downtime due to breakdowns, enabling your business to meet deadlines and customer demands more consistently. Furthermore, these machines often come equipped with advanced technology that can enhance operational precision, ultimately leading to a superior end product. In this way, a well-thought-out investment in a quality cutting machine can pave the way for improved operational efficiency and larger profit margins in the competitive market.

Related Posts

-

10 Innovative CNC Press Brake Machine Features You Should Know

-

Exploring Innovative Uses of Sheet Metal Fabrication Machines in Modern Industries

-

How to Optimize Your CNC Plasma Cutting Machine for Maximum Efficiency and Precision

-

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

-

How to Choose the Right Sheet Metal Fabrication Machines for Your Business Needs

-

Revolutionizing Manufacturing: The Future of Sheet Metal Laser Cutting Machines in 2024