- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

Top CNC Press Brake Machine Tips for Optimal Performance?

In the world of metal fabrication, optimizing the performance of a CNC press brake machine is crucial. This machine is designed to bend metal sheets with precision, which makes it an essential tool in many industries. To achieve the best results, understanding the functionality and maintenance of the CNC press brake is vital.

Many operators overlook simple issues that can reduce performance. Regular calibration of the machine is often neglected, leading to inaccurate bends. Additionally, insufficient training in using the CNC press brake can result in inefficiencies and errors. It's important to recognize these gaps and strive for improvement.

Proper tooling and setup play a significant role in the effectiveness of the CNC press brake machine. Selecting the right tooling can influence the quality of bends. Equipment must also be matched correctly for the job. Investing time in these details helps prevent mistakes and enhances productivity. Adopting a proactive approach can lead to remarkable improvements in performance.

Choosing the Right CNC Press Brake Machine for Your Needs

Choosing the right CNC press brake machine is crucial for any metal fabrication shop. With various options available, it’s essential to understand the specific needs of your operations. A recent industry report shows that inadequate machine selection can lead to a 30% drop in productivity. Failing to assess the workload can harm efficiency in the long run.

Consider the bending length and tonnage. A machine with insufficient capacity can hinder production. Industry experts recommend calculating the maximum load to avoid mistakes. Moreover, look into the precision required for your projects. A tolerance of ±0.1 mm is standard for many applications, but certain tasks demand higher accuracy. It's vital to discuss your needs with experts to avoid unnecessary compromises that can lead to rework and wasted materials.

Another aspect often overlooked is the machine's adaptability. Different projects may require diverse tooling and setup adjustments. Machines that are difficult to adapt can slow down production. A flexible machine allows for quicker changeovers. This can drastically improve overall performance and reduce bottlenecks. Investing time in assessing these factors now can save money and frustration later.

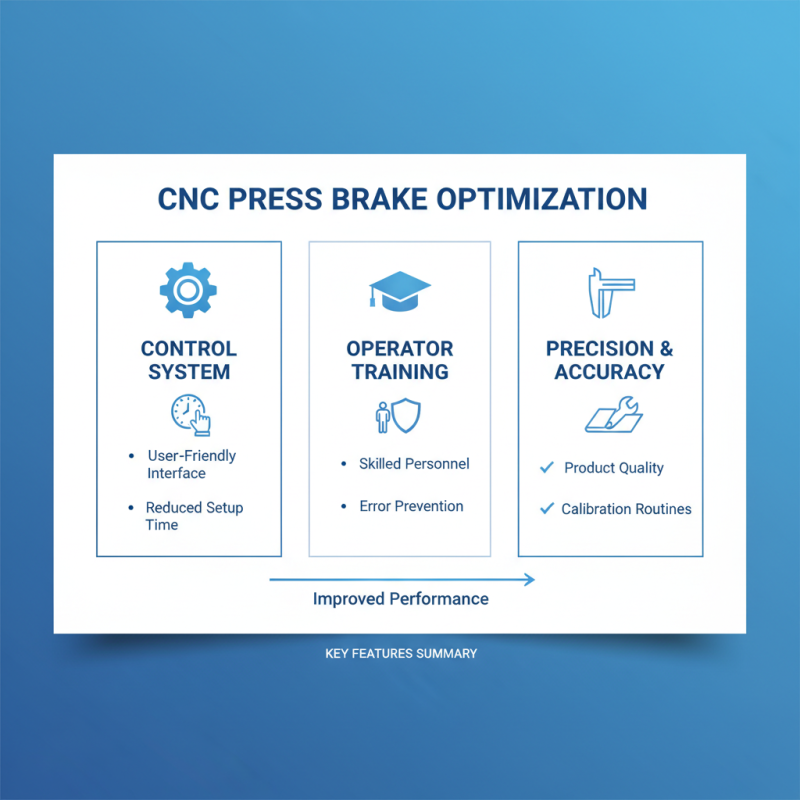

Understanding the Key Features for Optimal Performance

When it comes to optimizing the performance of a CNC press brake machine, understanding key features is essential. The most crucial aspect is the machine's control system. A user-friendly interface can significantly reduce setup time. Operators must be trained adequately to avoid mistakes during complex tasks. The precision of the machine, influenced by its back gauge and bend angle, determines the quality of the finished product. Accuracy is vital, yet many operators still overlook calibration routines.

Another important feature is the hydraulic system. A well-maintained hydraulic unit ensures consistent pressure during operations. However, some operators skip routine inspections, leading to performance issues. Regular checks could prevent unexpected downtime. Tooling also plays a crucial role; appropriate dies and punches can make or break a project. Selecting the right tool is often underestimated.

Finally, software capabilities can enhance productivity. Advanced programming features allow for more intricate designs. But software bugs or user errors can complicate workflows. Operators should be reminded to consult manuals regularly. Performance optimization requires constant reflection and skill improvement. Understanding and utilizing these features can lead to significant gains in efficiency and output quality.

Best Practices for CNC Press Brake Maintenance and Care

Maintaining a CNC press brake is essential for optimal performance. Regular checks on hydraulic fluid levels keep the system running smoothly. Dirty or low fluid can lead to unexpected shutdowns. Clean filters should be checked often to avoid overheating, which could cause damage. Ignoring these small issues can lead to costly repairs later.

Lubrication is crucial. Applying the right lubricant to moving parts minimizes wear and extends the machine's life. But it's easy to overlook this step in a busy workshop. Operators should create a lubrication schedule. This keeps the process on track. Additionally, regular inspections of tooling and dies are necessary. Misalignments or damages can result in inaccurate bends and wasted materials.

Operators must also consider environmental factors. Dust and debris can affect performance. Keeping the workspace clean is a simple yet often neglected task. Inadequate cleaning may cause issues in precision and lead to mistakes. Adopting best practices is about consistency and awareness. Each small effort contributes to a more efficient operation. Regular care assures the press brake's longevity and reliability.

Top CNC Press Brake Machine Tips for Optimal Performance

| Tip Category | Tip Description | Frequency | Importance Level |

|---|---|---|---|

| Daily Maintenance | Check hydraulic fluid levels and top off as necessary. | Daily | High |

| Weekly Inspection | Inspect and clean the CNC control unit for dust and debris. | Weekly | Medium |

| Monthly Calibration | Calibrate the machine by checking alignment and angle accuracy. | Monthly | High |

| Quarterly Audit | Perform a comprehensive check of all mechanical components. | Quarterly | Medium |

| Annual Overhaul | Schedule a complete machine overhaul with a qualified technician. | Annually | Critical |

Common Mistakes to Avoid When Operating CNC Press Brakes

Operating a CNC press brake requires attention to detail and an understanding of common pitfalls. One frequent mistake is improper setup. If the machine is not aligned correctly, it can lead to inaccurate bends. Take the time to check your die setup and ensure proper alignment. Neglecting this can cause issues down the line.

Another common issue is overlooking the materials. Different metals require different bending techniques. A wrong choice can lead to material wastage. Don't assume one setting fits all materials. Always verify the specifications for each metal type before starting.

Lastly, operators should avoid rushing the process. Speed can compromise quality. Take your time with adjustments and movements. In the long run, patience can save time and resources.

Tips for optimal performance include regularly maintaining the machine. Check for any wear on components frequently. Ensuring everything is running smoothly can prevent unexpected downtimes. Keeping a clean workspace also helps in maintaining focus, reducing the chance of mistakes during operation.

Tips for Enhancing Precision and Efficiency in Sheet Metal Bending

When it comes to enhancing precision and efficiency in sheet metal bending, understanding your CNC press brake is key. The right setup and operation can significantly influence the outcome. One crucial aspect is ensuring the material is properly aligned. Misalignment can lead to defects, wasting time and resources. An additional step in checking the alignment may seem tedious, but it can prevent costly mistakes.

Regular maintenance plays a vital role in performance. Dust and debris can accumulate over time. This buildup can affect the precision of bends. It's important to establish a routine cleaning regimen. Keeping the machine well-maintained not only improves accuracy but also extends its lifespan. Don't wait for obvious issues. Inspect regularly and address minor problems before they escalate.

Operator training is another essential factor. An experienced operator knows the machine's nuances. They can adjust the settings for different materials. This adaptability enhances efficiency. Short training sessions can help even seasoned workers refine their skills. Sometimes the smallest adjustments lead to significant improvements in output quality and speed. A little focus on training pays off in the long run.

Related Posts

-

Why CNC Press Brakes Are Transforming Sheet Metal Fabrication Efficiency in 2023

-

Innovative Solutions for Efficient CNC Press Brake Machine Operations

-

10 Innovative CNC Press Brake Machine Features You Should Know

-

Maximizing Metal Forming Efficiency: The Evolution and Future of Brake Press Machines in Manufacturing

-

Top Sheet Metal Folding Machine Buying Guide for Beginners and Expert Users

-

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing